SwissQ

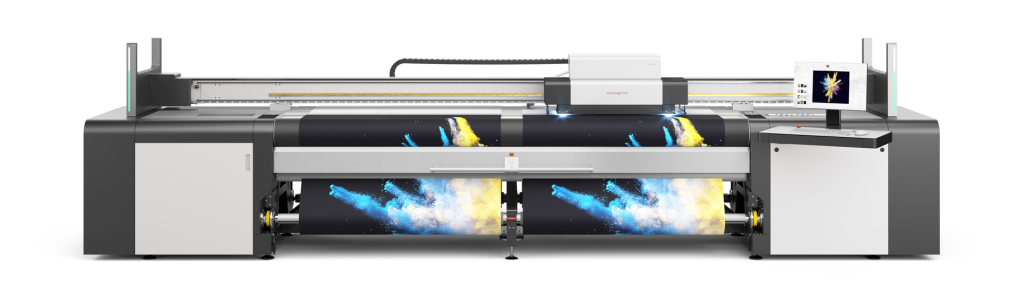

Kubiru S

The remarkably productive roll to roll printer

High throughput with outstanding quality. That’s what Karibu S delivers – combined with ultra-simple handling, high reliability and great versatility. Thanks to a rock-solid foundation and comprehensive equipment.

3.4m

Width

For single and 1.6 m dual rolls

1080 dpi

Resolution

Impressive results

330 m2/h

Productivity

Pays off in no time

1

Colour in addition to CMYK

What about white?

Karibu, the unique roll to roll printer

Here comes the second generation – with state-of-the-art print head technology – for the highest output quality you have ever achieved in UV roll to roll printing to date. And still with the unique features that users so appreciate. Because they make work much easier, as well as creating real competitive advantages.

Even more efficiency

A printer that is just as intuitive to operate as the output software. A cassette system for fast loading and changing of rolls. The built-in Light Box for immediate and continuous quality control of backlit prints. Thanks to the Mesh Kit, printing mesh is effortless and clean with no liner necessary. And the double-sided printing option turns out this kind of production automatically and reliably.

Even more reliability

Karibu is precise, robust and durable, as expected of its swissQprint DNA. The same with regard to excellent energy efficiency – although this is only one of the reasons for the exceptionally low total cost of ownership. Another: extremely high system availability thanks to minimal maintenance requirements.

Even more applications

Cool LED technology gives you extensive freedom of choice in materials. The specially developed ink set adds an extra touch: made for roll printing, it offers impressive flexibility, adhesion and a large colour gamut. With a formulation that is friendly to health and the environment (Greenguard Gold certified), printed products are even allowed into hospitals.

Even higher quality

Karibu 2 outputs resolution and quality that will leave even your most demanding customers speechless: 1350 dpi, with every droplet placed spot-on. For homogeneous and sharp images in backlit applications, fine art and photo prints. Karibu 2 also gives you new production modes with increased output – while maintaining superb quality.

Cassette system

For fast and dependable roll handling

Any roll is loaded and ready to print within minutes, following just a few simple steps. Changing from one job to the next is equally fast, no matter how different they may be. Even novice users can easily operate the cassette system:

Slide the material onto the pneumatic roll holder, centre and secure it. Then pull a length of material over the print bed, secure it to the empty cardboard core at the front and close the cassettes on both sides. Now the only thing left to do is enter printing and material parameters into Lory, the output software, and production can start. Sensors and controllers inside the cassettes ensure correct web tension from the first to the final metre on the roll. The operator can easily switch to other tasks meanwhile, or simply take a break while counting on Karibu to do a great job.

Light Box

For convenient on-the-spot inspection of backlits

Karibu is a specialist at producing backlit prints. Especially since this roll to roll printer – like all swissQprint machines – is a champion at precise droplet positioning. In addition, it offers high-resolution print modes in various increments. For quick and convenient quality control of backlits, the Light Box is right next to the printing area. So should optimisations prove necessary, neither much material nor time has been lost. The Light Box is divided into 48 LED segments. The system illuminates only the exact number required for the defined roll width. And if on occasion that is still dazzling due to the design being printed, they can be dimmed.

Mesh Kit

For clean and efficient mesh printing

Karibu makes it a pleasure for you to include full bleed prints and prints on permeable substrates in your offering. Both are clean and simple, using the Mesh Kit integrated with the print bed. All you need to do beforehand is send the beam from the standard to the mesh position. That’s it. The Mesh Kit contains two rolls of paper that absorb excess ink. Don’t worry, the paper will never soil the substrate from below: first, it is slightly recessed and second, the absorbed ink cures during printing. Moreover, the paper moves along in conveyor belt fashion. All you need to do is occasionally change the full paper rolls, at the earliest after 600 linear metres of production. Cleaning is unnecessary.

Single or dual rolls

For optimum productivity

Karibu accepts rolls up to 3.4 metres wide and processes any job precisely and reliably. It becomes especially interesting if you routinely process narrower rolls up to 1.6 metres wide. Then you have a simple way to double your output by loading two side by side. For this, Karibu has a dual roll option that allows parallel production of two identical or different designs. Sensors and the control system continuously ensure optimal tension in both rolls, for impeccable parallel production.

Double-sided printing option

For automatic double-sided production

Karibu can handle double-sided printing. And it does the job automatically. The reliable, efficient way to produce ceiling hangers, blockout banners, stretch banners and double-sided posters.

An intelligent camera system controls the process: it uses QR codes printed next to the images to recognise the files that are due to be printed on the reverse side, and forwards the information to the control – including coordinates, so the subjects are correctly aligned and congruently superimposed.

Multilayer printing

Registration accuracy in multilayer printing

Do you print window films or other transparent media, maybe with double-sided images and text? Then you will like multilayer mode. Whether mirrored, identical or different, Karibu prints multilayer designs on the medium with accurate registration. There is no chance of bleed-through because all the layers are printed in one go.

White plays a crucial part in multilayer printing: as overprint (colour + white) or underprint (white + colour), for day and night applications (colour, white, colour) or for five-layer prints (colour, white, blocker, white, colour). Karibu easily handles them all.

Tip Switch Vacuum

For effortless vacuum control

Operators will become vacuum virtuosos. Because it feels like playing the piano – only you need just one finger: run it over the vacuum tip switches across the print bed width and open all 136 vacuum channels in just four seconds (patent pending). Once the roll is loaded, do the same to shut off channels to its left and right. And in the case of dual rolls, also the channels in the gap between them.

Masking is now a thing of the past as you can switch the vacuum on or off in very small segments to avoid leaks. This allows the vacuum to develop its full force exactly where needed and securely hold down the substrate. To help you keep track, each switch has a green and red indicator to show its open or closed status.

Incidentally, setting the vacuum is just as easy as the mechanical adjustment of it. It is done via Lory, the output software, which also ensures reliable feeding of material in combination with the machine control system.

Lory, the output software

For intuitive working

The output software is intuitive, logical and process oriented. Helpful tools and features help you work productively and efficiently. You have a great deal of freedom before pressing the start button. Even settings are possible that would normally require a new RIP run. You constantly keep track of things via the graphical user interface.

Just like Karibu, Lory is a 100 percent swissQprint in-house product. Based on decades of experience, designed and implemented throughout as a state-of-the-art software solution. We worked closely with RIP vendors during development. As a result, Lory integrates with end-to-end workflows and you exploit the full potential of process optimisation.

Lory is based on modern software architecture, so it is robust and open for the future. This in turn is a tremendous motivation for our software engineers, priming them to address and implement new market requirements as they arise. That means you as a user have the all-round optimal solution for today and tomorrow.

Graphical user interface

Assemble jobs by drag-and-drop onto a virtual roll. You receive continuous visual feedback to get the most out of your substrates. You also stay flexible: Lory is there to assist should you decide to print a single design multiple times on one roll, or maybe cluster several different designs. And all of this without going back to the RIP.

Material database

Lory includes a database of materials tested by swissQprint, and is readily extensible with ones you keep in stock. Once configured, each material can be retrieved again and again. Lory then sends parameters such as web tension, vacuum and material thickness to the machine controller. This reduces setup time and assures process reliability.

Statistics

Lory logs the complete job history. The data collected provides information for operational and orderrelated final costing: ink consumption, number of square metres printed, printing time per job or time period, etc. The economist in Lory thus supports you in optimising added value.

Colours

9 colour channels are available.

UV inks

Karibu prints using UV inks specially developed for roll printing, with a large colour gamut. They are flexible and adhere to all common materials: backlit media, textiles, vinyl films, banners, mesh, wallpaper and many more.

We attached great importance to environmental and health compatibility in their formulation. The inks are low-odour and therefore pleasant to use. They contain no NVC, a toxic compound found in many conventional UV inks.

Karibu ink is Greenguard Gold certified, which means that it meets strict criteria for the safety of susceptible individuals such as children, the elderly and the sick. Accordingly, the printed products are fine for use in schools and healthcare facilities. An opportunity for you to target new segments.

Light colours

Light cyan, light magenta and light black reproduce natural skin tones, subtle gradients and shading. For fine art productions that live up to their name.

White, Varnish

White, as a base layer or printed selectively, is a highlight with transparent and dark media. Effect varnish, applied partially or across the whole substrate, produces visual and tactile experiences.

Process colours

Inkjet printing is as colourful as the world around us. The CMYK that comes as standard with all swissQprint systems is expandable, either when a printer is initially equipped or later when the requirements change. Nine freely configurable colour channels are available.

Orange

Orange significantly expands the colour gamut in orange and red tones. This helps to reproduce corporate colours even more accurately.

Neon

Attention grabbers: neon yellow and neon pink give printed materials that sensational look. And they are fluorescent in black light.

Special features

Extras elsewhere, but standard from swissQprint

X-Control

Karibu’s beam is movable between two defined positions: standard and mesh. With small adjustments, it can also compensate feeding errors. Moreover, X-Control facilitates a flatbed-like printing mode for test prints – simply lay the material on the printer, rather than having to load a roll.

Profitable LED technology

LED curing is cool. This means heat-sensitive media can join the portfolio and open up lucrative markets. LED lamps are always ready to go, with neither a warm-up nor a cool-down time. In addition, they are me- chanically robust and maintenance-free. LED also pays dividends due to high system availability and low maintenance requirements.

Certified energy efficiency

swissQprint LED systems are all proven to be highly energy efficient (ISO 20690:2018). As an owner, you can not only reckon with low operating costs but also look forward to conserving valuable resources.

Economical and environmentally friendly

With swissQprint, you can print with a clear conscience. No ozone, barely any rejects or waste, and modest maintenance requirements keep the environmental footprint small.

Constant print quality

swissQprint large format printers comply with the Fogra PSD. They can integrate with a PSD workflow and deliver constant print quality with faithful colour results.

Total control

The operator can keep an eye on Karibu from anywhere in the printing room, thanks to two status indicators at each end of the print beam. Bar displays light up in various colours to communicate the machine status and printing progress.

Special features

Extras elsewhere, but standard from swissQprint

Safety for people and processes

Should something or someone breach the light curtain surrounding the beam, the print head carriage slows down to warn as well as protect the operator. Meanwhile, printing continues. There is no loss of time or material.

Edge restraints

Stainless steel edge holders prevent crashes and interruptions to operation by keeping wavy material edges flat, with both single and dual rolls.

No crushing crashes

Crash Sensor Technology prevents damage and rejects if the material thickness was entered incorrectly or edges of the material are sticking out, for instance. The print head carriage stops if there is a hazard, and later continues at the exact pass position.

Clean cut

The print bed incorporates a cutting channel that provides a defined trimming edge. So, out with the cutter and slice it through. The printed roll is cleanly detached, ready for finishing and delivery. And the rest is ready for the next job.

Precise droplet placement

The material and the environment together generate an electrostatic charge. Antistatic units on the machine neutralise it, so that the tiny ink droplets land exactly where they should and produce an impeccable overall image.

Resume printing after a crash

Despite all precautions, there has been a crash, and that on the final few meters? It’s not the end of the world. Via the output software, the operator resumes printing at the exact point where it stopped – and saves the day.

Technical specifications

| Print area | 3400mm |

| Material thickness | maximum 3mm |

| Roll width | maximum 3400mm / dual roll 2x1626mm |

| Roll weight | maximum 200kg / dual roll 180kg |

| Roll diameter |

maximum 380mm pneumatic roll holder for 3” core diameter |

Equipment/Options

| Curing | UV-LED |

| Double-sided printing | option |

| Dual roll option | 2x1626mm |

| Casette system | standard |

| Light Box | standard |

| Mesh Kit | standard |

| Tip Switch Vacuum | standard |

Colours

| Colour channels | Maksimum 9 |

| Print heads | Maksimum 18 |

| Print heads per channel | 2 |

| Light cyan, magenta, black | ✓ |

| White | ✓ |

| Varnish | ✓ |

| Orange | ✓ |

| Neon pink, neon yellow | ✓ |

Inks

| Integrated ink supply | CMYK in 5 litre containers / white 5 or 1 litre containers |

| UV-curable inks | ✓ |

| Solvent-free (no VOCs) | ✓ |

| Greenguard Gold certification | ✓ |

| NVC-free | ✓ |

| White feed and maintenance system | Potpuno automatsko |

| Indoor and outdoor applications | ✓ |

Resolution

| Addressable resolution | Do 1080 dpi |

| Visual resolution | Do 2160 dpi |

Dimensions and weight

| Dimensions (L × W × H) | 1,36 x 6,36 x 1,65 |

| Weight | 2000 – 2100 kg (depending on configuration) |

| Safety standards | meets industry standards |

Installation environment

| Power supply | 3 x 400V, 3L + N + PE (50/60Hz)

3 x 480V, 3L + N + PE (60Hz) 3 x 208V, 3L + PE (50/60Hz) excellent energy efficiency according to ISO 20690:2018 |

| Temperature range | +20°C to +30°C |

| Relative humidity | 40% do 80% non-condensing |

First-class heritage

swissQprint large format printers contain 100 percent Swiss engineering and machine-building work. Now in Karibu, the latest technologies meet up with over 20 years of development experience.

Our internal lines of communication are short, which makes us agile and effective. Working right next door to the development department, our production team assembles each printer by hand. In the case of Karibu, from around 2000 individual parts, over 90 percent of which come from Switzerland.

swissQprint delivers comprehensive and reliable solutions

Each element of a swissQprint system is carefully matched to the cleverly thought-out whole: from the mechanics to the control system and the output software. This is because our engineers at headquarters work hand in hand. Furthermore, we operate an in-house ink laboratory that is the interface to our ink suppliers. This ensures that the inks keep pace with our developments and perform consistently.

swissQprint is represented around the globe

Our subsidiaries and sales partners speak your language and support you in every way. Thanks to local warehouses you can rely on fast delivery of consumables and spare parts. All technicians undergo thorough training at swissQprint headquarters. You can therefore count on professional maintenance of your printer and spot-on assistance with both technical and application queries.