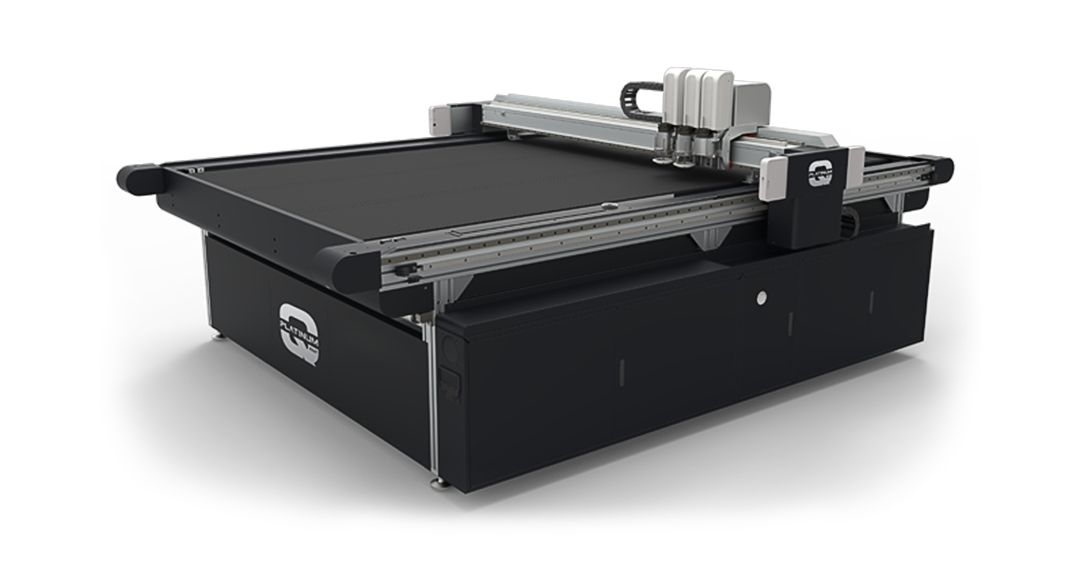

LIYU

Platinum Q-Cut 2516

General Information & Highlights

Equipped with high precision CCD camera, the system realizes automatic position on all kinds of materials, automatic camera registration cutting, and solves problems of inaccurate manual position, and print distortion,thus to complete procession task easily and precisely.

Cutting speed can reach to 1.5m/s, which is 4-6 times of traditional manual way. Intelligent control system of Z-axis height decreases cutting tools’ moving distance, shortens working time and thus improves the production efficiency.

In order to meet different industrial cutting requirements, the cutting head can be flexibly chosen from the standard head, punching/notching head, and the milling head.

The depth of cutting tool can be controlled accurately by the automatic knife initialization system.

Equipped with double beams cutting system, can highly increase your production efficiency.

With the intelligent conveyor system, to achieve cutting and picking up the samples at the same time. It totally saves the labor cost and improves the efficiency significantly.

To strengthen the stability of the machine, Q-2 adopts new aviation aluminum material with high intensity, corrosion resistance and strong tenacity. At the meantime the design of Q-2 system is ergonomic friendly which allows you to have better humanized experience of operation control and processing materials.

The modularized working area can be added according to customers’ requirements.

Application of aviation aluminum honeycomb panel, making the inside air of panel moves freely, ensures the stability of structure without the influence of thermal expansion and contraction effect. Meanwhile, mutually constrained dense cells respectively and averagely bear the force from the panel to ensure the high- level flatness of the working table even of quite large size.

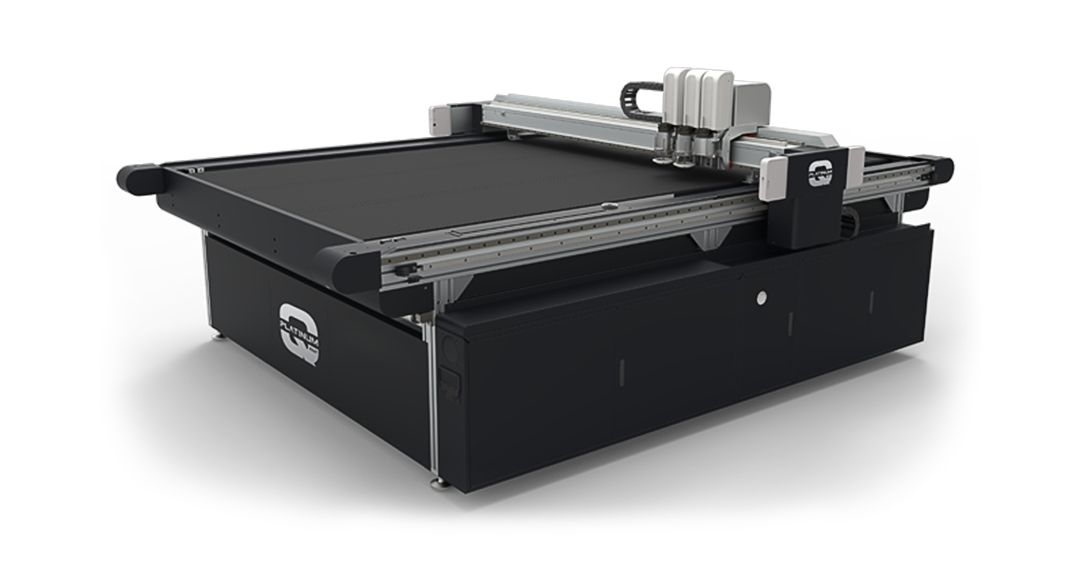

Specifications:

Cutting Accuracy

± 0.1mm

Cutting Area

2500mm x 1600mm

Data Format

PLT, DXF, HPGL, PDF, EPS

Max. Cutting Speed

1500mm/s

Maximum thickness

45mm

Power

10 KW

Power Requirements

380v +/- 10% 50HZ

Tool Holder Type

EOT, UCT, KissCUT, PEN