SwissQ

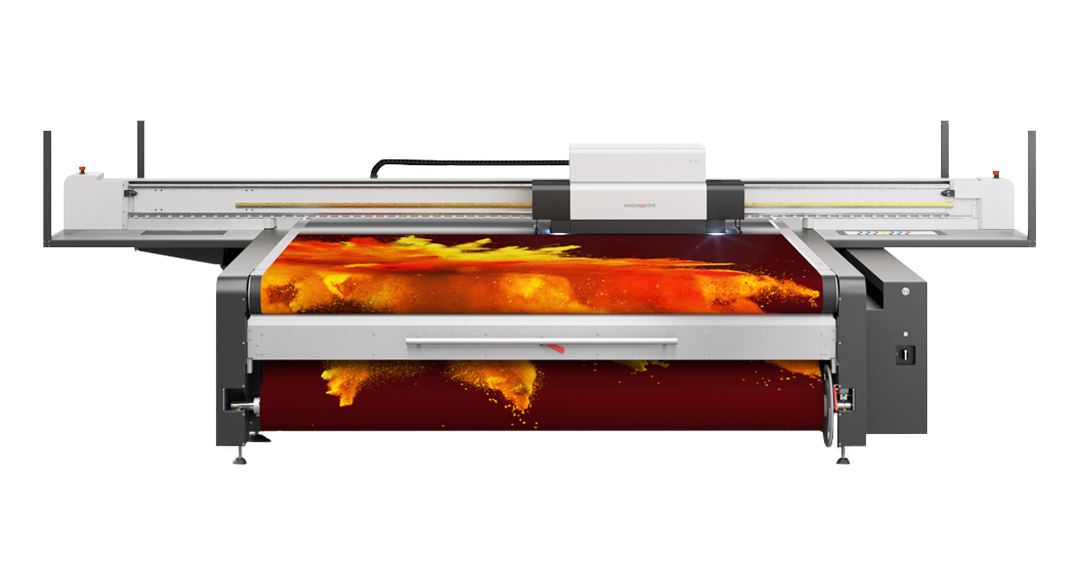

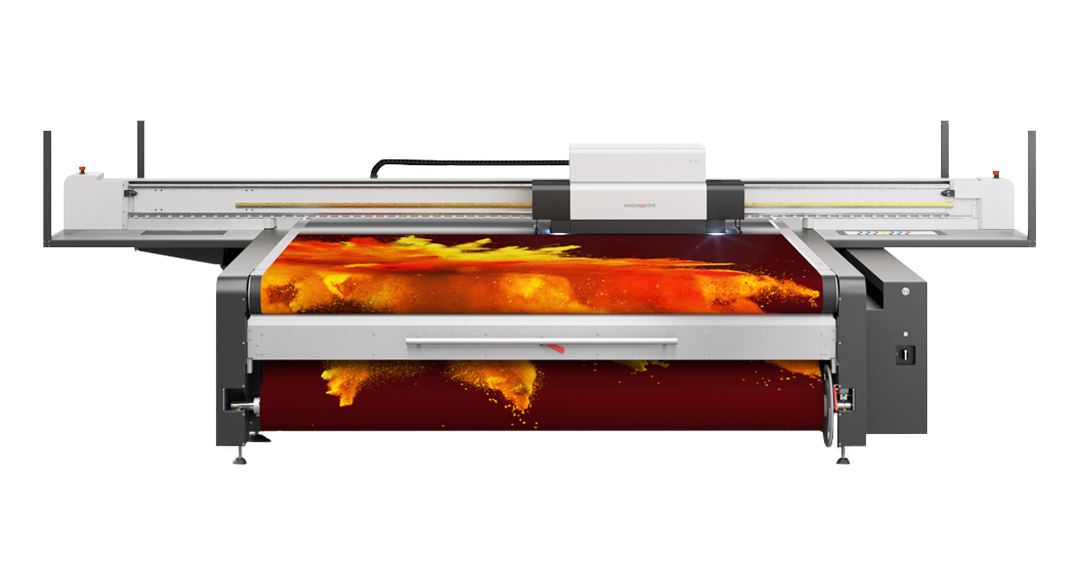

Oryx 4

The ideal printer for ambitious newcomers

Oryx 4 is the most performant entry-level flatbed printer out there. It outputs quality work at up to 90 m²/h. It offers nine freely configurable colour channels. And it is just as reliable, robust and low-maintenance as its siblings.

2.5m

Flatbed

2.5×2m

1080 dpi

Resolution

Impressive print results

90 m2/h

Productivity

With high precision

5

Colours in addition to CMYK

Custom-configurable

High-End UV-LED flatbed printers

Flatbed generation 4

Our company founders have been active in digital printing for 25 years. Indeed, they have been a shaping force. Their high aspirations have also shaped the company. And the market agrees: swissQprint is synonymous for precise, practice-oriented and reliable technology. Our Nyala model has been the leader in European UV inkjet printing for six years. Which gives us incentive to raise the bar a little higher with each machine generation – with an eye to keeping you ahead of your competition.

Step ahead

Impala 4 and Nyala 4 redefine premium quality with their resolution of up to 1350 dpi. Then there are new production modes that deliver increased output at top quality. This is thanks to the latest print head technology in combination with high-precision droplet placement perfected by swissQprint. Oryx 4 now comes equipped with high-performance print heads, making this machine almost 40 % more productive than its predecessor. It is the entry-level model in a class of its own.

Unique vacuum system

All Generation 4 printers feature the unique Tip Switch Vacuum. 256 individually adjustable vacuum segments mean you can achieve the perfect vacuum for any substrate size. You can open or close segments quickly and easily. Even between media. And whatever its dimensions. Air leakage and masking are things of the past. The future is fine-tuned vacuum control and efficient working in a quiet environment. Because the vacuum pumps are pleasantly quiet. Power-saving, too.

Individual configuration

With a swissQprint flatbed printer you get the solution you need. And you can readily adapt the original configuration to new requirements. After all, our systems have always been modular. Generation 4 offers you a wide range of options. Talk to us about configuring the printer that is just right for you.

Single or dual roll option

Films, banner, mesh or other roll stock up to 180 kg, swissQprint systems can handle them all – even the heat-sensitive ones thanks to LED curing. And that across the full printing width of 2.5 metres (Oryx / Impala) or 3.2 metres (Nyala). Setting up and changing rolls is easy, and once the job is started the machine continues working without supervision. When necessary, multiple colour layers can be applied in one pass for pinpoint registration.

The integrated spreading roller helps prevent crashes by smoothing the material before it runs crease-free over the print bed and is rewound cleanly on the opposite side. This already stable system has a controller that ensures a flawless print image by continuously regulating the tension. The spreading roller also serves to dissipate static charge from the material, aiding precise droplet placement.

With the dual roll option the printer processes two rolls up to 47 inches (Oryx/Impala) or 60 inches (Nyala) at once. You spotted it: this doubles productivity, whether you are processing two identical or different designs.

Board option

The swissQprint board option is the key to flawless printing on rigid media up to 4 metres long. It holds oversized panels firmly in place under full-power vacuum during the printing process. When the printing beam reaches the end of the table, a sophisticated feeding system takes over and advances the substrate automatically. Printing continues seamlessly as soon as the substrate is positioned exactly at the new zero origin.

The appeal of this process lies in a combination of absolute precision and high efficiency. The vacuum system assists you with positioning and moving: vacuum inversion creates a cushion of air so that materials weighing up to 100 kg literally float over the print bed, making it easy to handle the heavyweights.

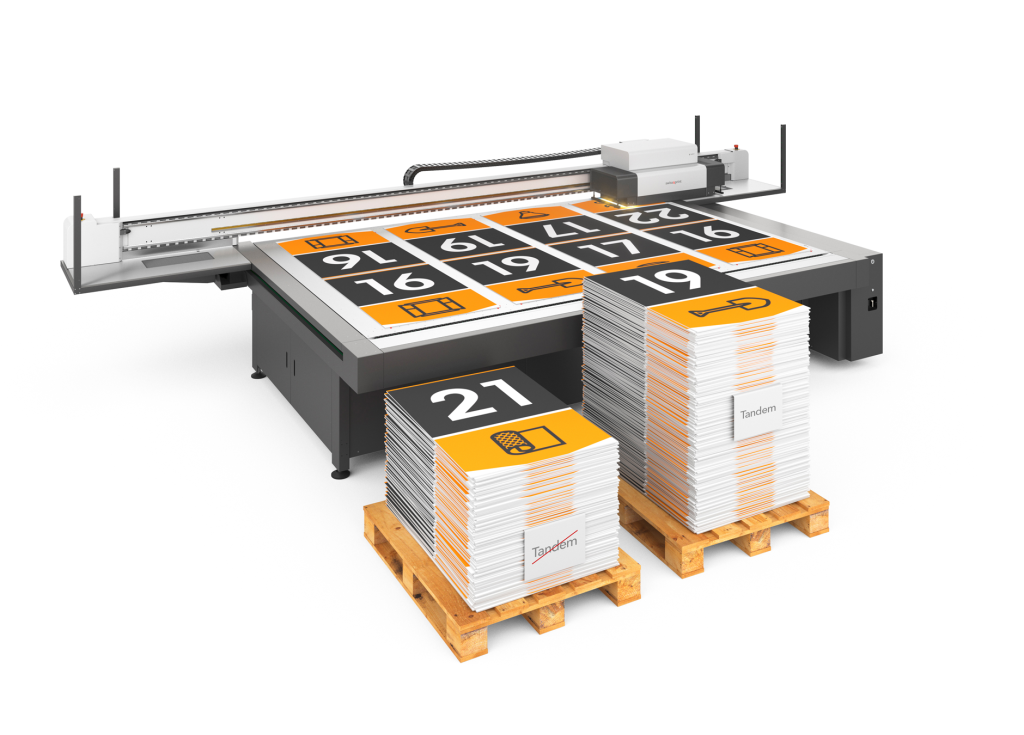

Tandem

In tandem operation, machine and operator join forces for continuous, non-stop action: maximum productivity by the system, fitness training for personnel. The principle is straightforward: media can be loaded onto the printing table from both the front and rear. While printing is underway on one side, the operator loads the other side, and vice versa – so work continues without interruption.

The vacuum table has a front and a rear section. In addition, the Tip Switch Vacuum allows vacuum channels to be switched on and off segment by segment across both areas. Vacuum to the rear section can be shut off when normal jobs are being printed on the front section only – no masking needed.

With Tandem: 245 panels/hour

Without Tandem: 143 panels/hour

Practical test

Producing 700×1000mm panels on a Nyala 4 in speed mode.

Result: 71% higher productivity with Tandem.

Tip Switch vakuum

The vacuum table of the latest swissQprint generation is segmented into 256 parallel channels, each with its own vacuum switch controllable at the touch of a finger – this is Tip Switch Vacuum (patent pending).

You can close any segment quickly, easily and precisely: both on the left or right of the media, and in the gaps between individual boards or rolls. There is no air leakage and no need for taping. The vacuum exerts full power exactly where it should and reliably holds down substrates of any size. All the while, it works quietly and energy-efficiently because the vacuum pumps are underpressure-controlled.

To help you keep track, each Tip Switch has a green or red indicator to show whether its segment is open or closed. You save a lot of time by simply switching off particular zones instead of covering them. This also adds even more efficiency to the shadow file and step-and-repeat functions, as well as tandem printing.

Rob

The robot loads and unloads media onto swissQprint flatbed printers. Just a few simple steps and within ten minutes Rob is docked to the printer and ready to go. Another few mouse clicks to set up the job and then things can get started – without headaches or additional effort. Because this is where the output software takes over. It communicates both with trainable Rob and the printer.

The operator can easily switch to other tasks in the meantime, or even go home for the evening. Rob and the printer handle the extra shift all by themselves. Rob is ready for action 24 hours a day, 7 days a week. He takes care of routine work – with consistent precision and high efficiency.

Rob gets even higher utilisation out of every swissQprint machine. Customers benefit from shorter delivery times, while providers earn higher returns.

Colours

9 colour channels available

UV inks

Depending on your application focus, different ink sets are available. Graphic ink sets typically bond on acrylic, aluminium composite panels, wood, banners, polyester, polycarbonate, polystyrene, (rigid foam) PVC, vinyl films, flexible foam panels and numerous other media. For specialised printing on glass or metal, there are ink sets available with optimised properties.

We attach great importance to the environmental and health ramifications in the formulation of our inks. swissQprint offers ink sets that are VOC and NVC free. They are also Greenguard Gold certified, which means that they meet strict criteria. Accordingly, the printed products are fine for use in schools and healthcare facilities. An opportunity for you to target new segments.

You can rely on consistent ink quality because our in-house ink lab tests every batch before it is despatched to customers.

Light colours

Light cyan, light magenta and light black reproduce natural skin tones, subtle gradients and shading. For fine art productions that live up to their name.

White, varnish, primer

White, as a base layer or printed selectively, is a highlight with transparent and dark media. Effect varnish, applied partially or across the whole substrate, produces visual and tactile experiences. Primer applies the foundation for printing onto glass and metal.

Process colours

Inkjet printing is as colourful as the world around us. The systems’ CMYK standard is expandable, either when a printer is initially equipped or later when the requirements change. Nine freely configurable colour channels are available.

Orange

Orange significantly expands the colour gamut in orange and red tones. This helps to reproduce corporate colours even more accurately.

Neon

Attention grabbers: neon yellow and neon pink give printed materials that sensational look. And they are fluorescent in black light.

swissQprint Greentech

Economic printing with a clear conscience

swissQprint users generate high value while keeping their ecological footprint small. That’s because we see equal importance in maximum customer benefit and environmental protection.

Profitable LED technology

LED curing is cool. This means heat-sensitive media can join the portfolio and open up lucrative markets. LED lamps are always ready to go, with neither a warm-up nor a cool-down time. In addition, they are mechanically robust and maintenance-free. LED also pays dividends due to high system availability and low maintenance requirements.

Economical and environmentally friendly

With swissQprint, you can print with a clear conscience, keeping the environmental footprint small: no ozone, barely any rejects or waste, and modest maintenance requirements.

Certified energy efficiency

swissQprint LED systems are all proven to be highly energy efficient (ISO 20690:2018). As an owner, you can not only reckon with low operating costs but also look forward to conserving valuable resources.

Features

Extras elsewhere, but standard from swissQprint

Cutting channel

The print bed incorporates a cutting channel that provides a defined trimming edge. So, out with the cutter and slice it through. The printed roll is cleanly detached, ready for finishing and delivery. And the rest is ready for the next job.

PSD compliant

swissQprint large format printers comply with the Fogra PSD. They can integrate with a PSD workflow and deliver constant print quality with faithful colour results.

Media diversity

Acrylic, aluminium composite panels, wood, banners, polyester, polycarbonate, polystyrene, (high-density) PVC, flexible foam panels, glass and metal – all routine work with swissQprint. Printing onto difficult, heat-sensitive materials such as textiles, films and paperboard is equally stress-free.

Registration pins

They are set in no time and help to make full and efficient use of the print bed: the swissQprint registration pins. Pegged onto a fine grid, they provide precise mechanical anchors on each side of the print bed. For any format and multiple copies.

Resume printing after a crash

Despite all precautions, there has been a crash, and that on the final few metres? It’s not the end of the world. Via the output software, the operator resumes printing at the exact point where it stopped – and saves the day.

Light curtain

Should something or someone breach the light curtain at the beam, the print head carriage slows down to warn as well as protect the operator. Meanwhile, printing continues. There is no loss of time or material.

Crash Sensors

Crash Sensor Technology prevents damage and rejects if the material thickness was entered incorrectly or corners on the medium are sticking out, for instance. The print head carriage stops if there is a hazard, and later continues at the exact pass position.

Simple series printing

Printing a series of identical or different subjects with no additional RIP process? Nothing could be simpler with the ‘step and repeat’ and ‘shadow files’ functions included in the output software. Just select the files, enter the number of repetitions desired, and off it goes.

Applications

Amazing things made easy

Multilayer printing

Transparency can be highly effective: multilayer printing comprised of process colours, foundation layer, blocking layer, foundation layer, and process colours again. And it is so easy to achieve. The layers are printed in one pass, by the way. So they overlap exactly – no chance of bleed-through.

Effect varnish

To lend printed items that certain extra, there is effect varnish. The scope is vast: printed selectively or across the whole expanse, as a light or heavy layer, with a matte to high-gloss finish – everything is possible. Then there is ink layering, which is able to produce Braille text and relief prints.

Droptix

3D visual effects on transparent media make an excellent eye-catcher. They are produced by printed lenses that work like a magnifying glass. The swissQprint Kea software assists with data preparation.

Flip – double-sided printing

You can produce double-sided prints with pinpoint registration in no time, even on inaccurately cut media. The swissQprint registration pins and the flip function give you perfect front-to-back registration, saving lots of time and waste.

The trick: simply register the same edge of the front and backside.

Technical specifications

| Dimensions

Flatbed, full bleed |

2500 x 2030 mm |

| Clearance | maximum 50 mm |

| Substrate weight | maximum 100kg/m2 |

| Roll width | maximum 2500 mm |

| Roll weight | maximum 180 kg / dve rolne po 100 kg |

| Roll diameter | maximum 360 mm |

Equipment / Options

| Curing | UV LED |

| Roll to roll option | 2500 mm x endless |

| Dual roll option | 2 x 1200mm x endless |

| Board option with extension tables | 2500×4000mm/max. 100kg |

| Tandem function | standard |

| Print area, Tandem each zone | 2500×1015mm |

| Tip Switch Vacuum | standard |

Colours

| Colour channels | maximum 9 |

| Print heads | maximum 9 |

| Print heads per channel | 1 |

| Light cyan, light magenta, light black | ✓ |

| White | ✓ |

| Varnish | ✓ |

| Primer | ✓ |

| Orange | ✓ |

| Neon yellow, neon pink | ✓ |

| Integrated ink supply | CMYKcmk, orange in 5 litre containers / white, varnish 5 or 1 litre containers / neon, primer 1 litre container |

| UV-curable inks | ✓ |

| Solvent-free (no VOCs) | ✓ |

| Greenguard Gold certification | ✓ |

| White feed and maintenance system | fully automated |

| Indoor and outdoor applications | ✓ |

Resolution

| Addressable resolution | Do 1350 dpi |

| Visual resolution | Do 2540 dpi |

Dimensions and weight

| Dimensions (L × W × H) | 2,51×5,04×1,42m |

| Weight | 1200 –1600kg |

| Safety standards | meets industry standards |

First-class heritage

For precision, reliability and durability.

swissQprint large format printers contain 100 percent Swiss engineering and mechanical build quality. The development department works right next door to where our production team assembles each printer by hand. Out of some 2200 individual parts, over 90 percent come from Switzerland.

swissQprint delivers comprehensive and reliable solutions

Each element of a swissQprint system is carefully matched to the cleverly thought-out whole: from the mechanics to the control system and the output software. This is because our engineers at the headquarters work hand in hand. Furthermore, we operate an in-house ink laboratory that is the interface to our ink suppliers. This ensures that the inks keep pace with our developments and perform consistently.

swissQprint is represented around the globe

Our subsidiaries and sales partners speak your language and support you in every way. Thanks to local warehouses you can rely on fast delivery of consumables and spare parts. All technicians undergo thorough training at swissQprint headquarters You can therefore count on professional maintenance of your printer and spot-on assistance with both technical and application queries.

Installation environment

| Power supply | 3 x 400V, 3L + N + PE (50/60Hz)

3 x 480V, 3L + N + PE (60Hz) 3 x 208V, 3L + PE (50/60Hz) Odlična energetska efikasnost prema ISO 20690:2018 |

| Temperature range | +20°C to +30°C |

| Relative humidity | 40% do 80% non-condensing |